Plenums: Our expert guide for flawless installation and optimal air diffusion!

Check out our comprehensive guide to metal or texture plenums

Plenums are an essential part of any high-performance air conditioning and ventilation system, and play a crucial and often little-known role. These essential components are located between the ducts and the air diffusers, and are required to ensure optimum air diffusion and ideal thermal comfort.

Traditional plenum installation methods present a range of challenges for HVAC engineers. Whether it is sizing, excessive weight, complex connections or difficulty when handling equipment in confined spaces, several obstacles may negatively impact the overall effectiveness of your ventilation system.

Several innovations have been developed to meet this challenge, chief among which is PLUMBOX, the CAIROX textile plenum. This innovative solution gives installers the tools they need to overcome the recurring challenges mentioned above. This plenum offers a radical transformation in the way we install air diffusion systems.

In this article, we will examine the challenges of installing plenums in greater detail, with a deep dive into how the sector’s latest innovations such as PLUMBOX can optimise energy efficiency while significantly simplifying operations for HVAC engineers.

I. Plenums in air diffusion: the basics

A plenum is a chamber or a space to which air flows from the main ducts, and which distributes this air to the diffusers. Its main role is to:

- Uniformly distribute the air into the diffuser

- Reduce the air speed before it is distributed into the room

- Reduce the noise generated by the air flow

The plenum significantly influences the installation’s overall performance. It is located at the end of the network, and is essential to ensuring the HVAC project successful achieves its purpose. As a result, great care must be taken when choosing which plenum to use, in order to ensure the ventilation system is effective.

Plenum styles

What types of plenum are there, and what is each type used for?

There are several types of plenum. Each is adapted to serve a specific purpose:

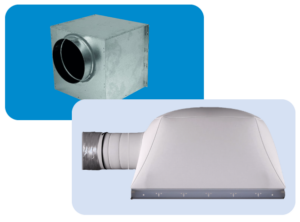

- Traditional metal plenums: These are sturdy but heavy, and see frequent use in commercial or industrial facilities.

- Composite material plenums: These are lighter than their metal counterparts, and provide good thermal and sound insulation. However, they are just as bulky as metal plenums.

- Textile plenums: Examples of this recent innovation include PLUMBOX from CAIROX, and are lighter, more flexible and less bulky.

II. Challenges of installing traditional plenums

While installing traditional plenums is a crucial step to ensuring the effectiveness of HVAC systems, it can pose certain challenges for HVAC professionals carrying out the installation. These obstacles can negatively impact the system’s overall performance and increase installation costs.

🟥 Weight and handling problems: Traditional plenums are generally heavy, which makes them difficult to transport on-site and can result in injury. Installing these plenums can also be particularly difficult in confined spaces.

🟥 Ceiling-related issues: Installing plenums in false ceilings may be particularly difficult, as the space between the ceiling and the false ceiling is often very limited and may contain a range of obstacles (including cables and pipes), in particular during renovation works. Sometimes it is necessary to create tailor-made plenums as the space is too confined, or to move the diffuser to another location, which changes the architectural character of the building.

🟥 Complex connections: Connecting plenums may be complex and time-consuming. It involves the use of specific tools, extended installation time and potential risks of air leaks at the connection points.

III. PLUMBOX: a revolution in plenum installation Plumbox is fire-resistant and compatible with all your tertiary building projects

By providing concrete solutions for the challenges faced by HVAC professionals, PLUMBOX represents a major breakthrough in plenum design for air diffusion systems.

Easy to transport and quick to install, it is the first ultra-light textile plenum and replaces heavy and bulky traditional metal plenums. It blends in perfectly with a wide range of elegant and stylish diffusers, which are adapted to interior decorations and add a touch of style to your ventilation system

PLUMBOX technical characteristics

Materials: Made from recycled polyester textile

Weight: Just 145 g, compared to its metal plenum counterparts that weigh several kilogrammes

Designed for transport: It can be folded into an A5 cover for easy storage and transport

Installation: Thanks to its self-gripping strap and elasticated opening, no tools are needed

Adaptability: Inflates and adapts to the limitations of the available space

Significant advantages

1- Simplified handling and transport: PLUMBOX’s ultra-light weight (145 g) makes it considerably easier to transport on-site and reduces the risk of injury to installers. PLUMBOX is easy to handle, transport and store due to its compact size.

2- Quick installation with no need for tools: Its self-gripping strap and elasticated opening means installation is quick and easy with no need for specific tools. Easy to install, with no tools: self-gripping strap (no need for self-drilling screws) and an elasticated opening to suit several different connection dimensions.

3- Reduced time spent working: Its streamlined installation process results in significantly reduced working time on-site, improving employee productivity.

A wide range of advantages

High performance & reduced carbon footprint

PLUMBOX also provides extra advantages beyond ease of installation:

1- Adaptive inflation: Incoming air inflates the plenum, causing it to expand to fit snugly in the space between the ceiling and the false ceiling. This is ideal for adjusting plenums to fit confined or unusually shaped spaces.

2- Recyclability and circular economy: Eco-design was central to PLUMBOX’s creation, and it is made from recycled materials and reused offcuts.

3- Reduced carbon footprint: With PLUMBOX, you can reduce your carbon footprint by 80% compared to traditional solutions. This reduction is achieved through the use of light, recyclable materials, as well as increased efficiency in manufacturing and transport.

4- This product is Made in France and Made in Europe – it’s as simple as that!